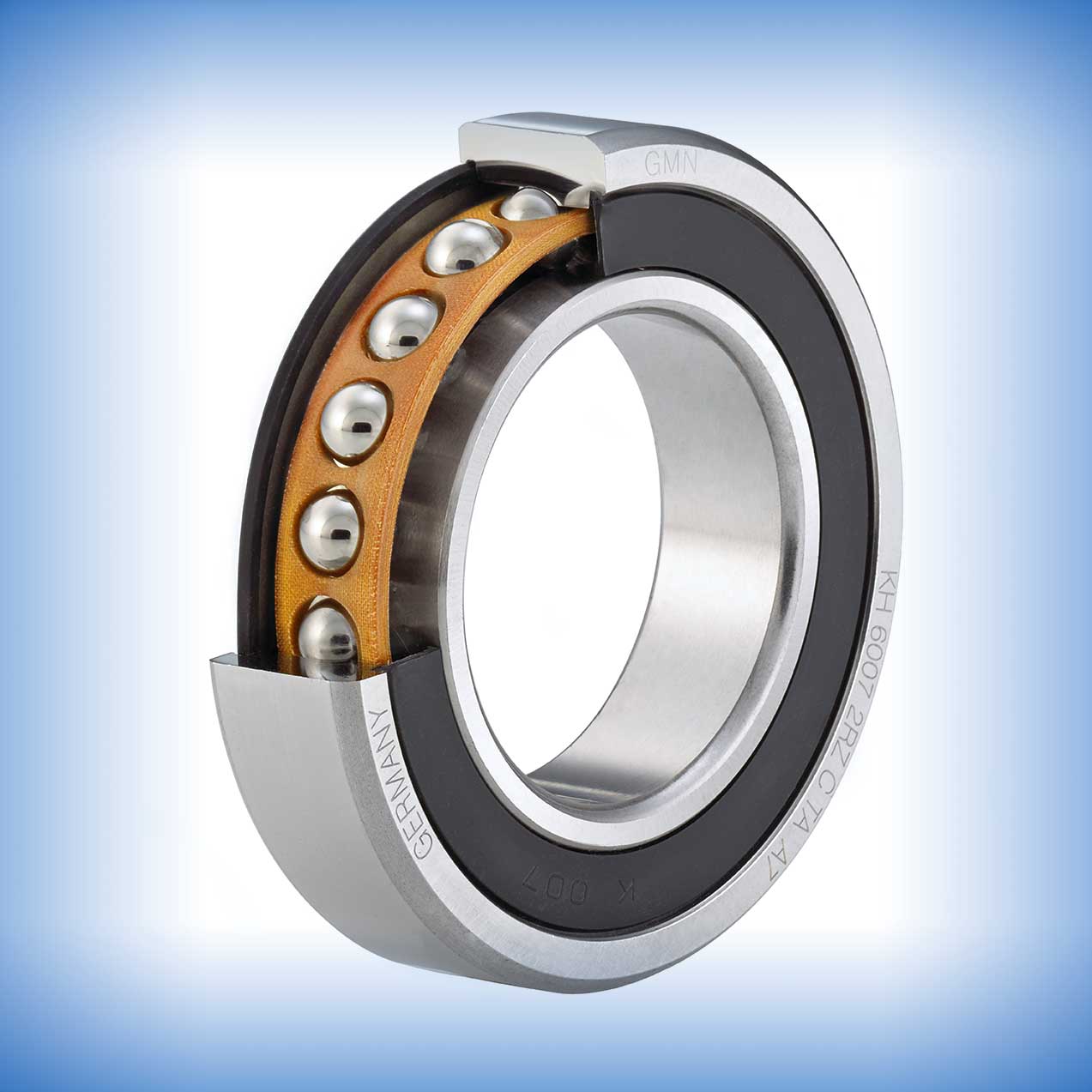

GMN Bearings

|

GMN produces one of the finest spindle ball bearings for the last 100 years. |

GMN Spindles

GMN – High Speed Grinding Spindles have been accepted world-wide as the standard for universal grinding machines.

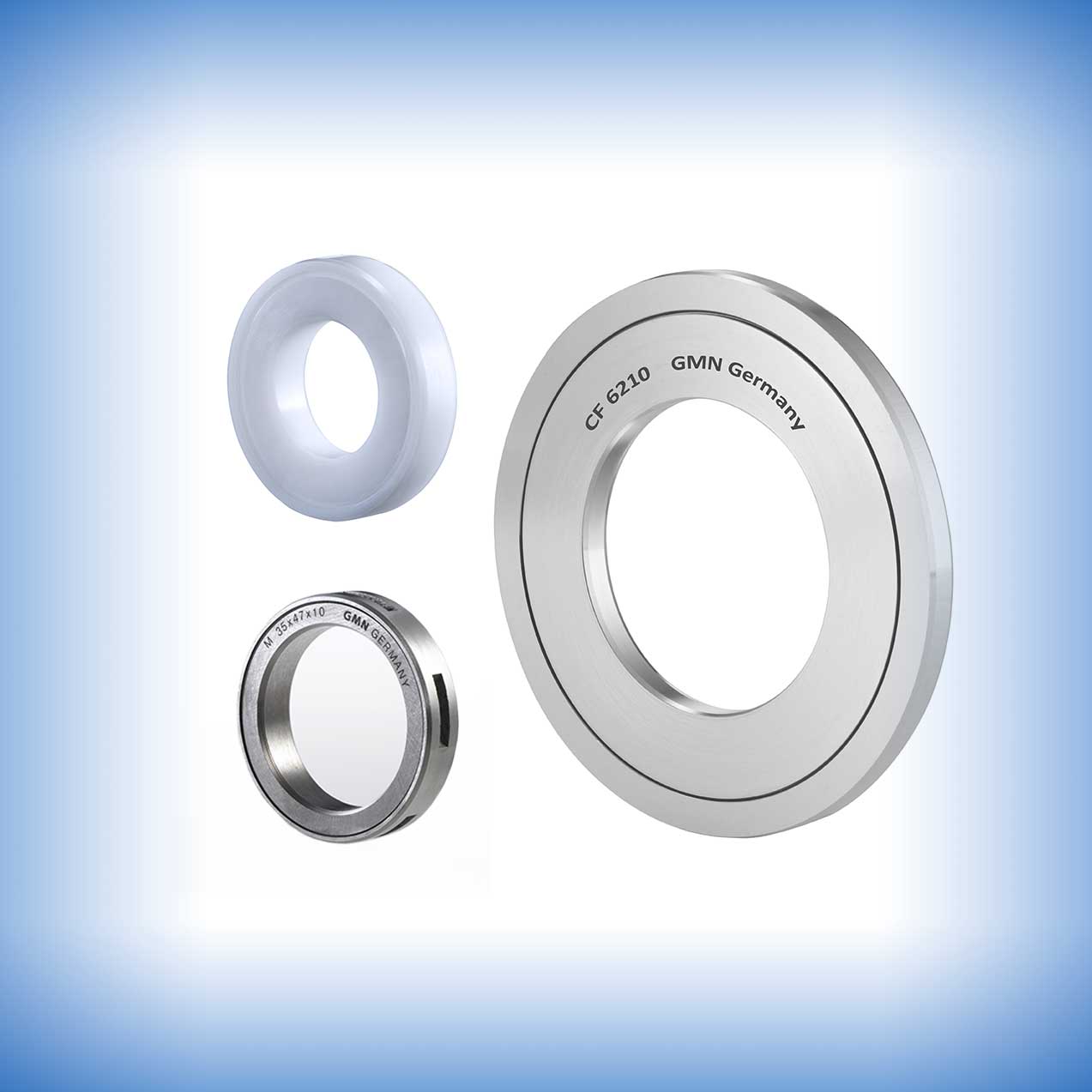

GMN Seals

| The GMN Non-Contact Seals are the right alternative for customer … |

SWC High Temperature Bearings

SWC supplies deep groove ball bearings of series 60, 62 and 63 for kiln truck applications.

GMN Freewheel Clutches

GMN clutches are widely used

for Backstop, freewheeling and

indexing applications

Download Catalogues

Please feel free to download required Catalogues from here.